+86 18038161406

+86 18038161406

Diodes Introduces Automotive-Grade AP61402Q Synchronous Buck Converter: 4A High-Performance Solution Redefines Automotive Power Design

Industry-Lowest 20μA Quiescent Current + Integrated EMI Optimization Technology Breaks Through ADAS Power Efficiency Bottlenecks

Recently, DIODES officially launched the AP61402Q automotive-grade synchronous buck converter. This AEC-Q100 Grade 1-certified device, with a 2.3V-5.5V input and 4A output, features ultra-low on-resistance MOSFETs (75mΩ/33mΩ) and patented gate drive technology, setting a new benchmark for automotive electronic power supply systems. In the harsh environments where infotainment systems must withstand extreme temperature differences from -40°C to 125°C and ADAS modules face 2MHz high-frequency interference, this solution achieves 95% peak efficiency (5V to 3.3V at 2A) through an innovative COT architecture, making it a game-changer in power supply design for electrified and intelligent vehicles.

Three-Core Technology Breakthroughs Address Industry Pain Points

Dynamic Energy Efficiency Dominance

Dual-mode modulation intelligent switching: By programming the EN pin voltage, the system can switch between PFM (pulse frequency modulation) and forced PWM modes. Test data shows:

PFM mode achieves 85% efficiency at light load (50μA) and a static current of 20μA, the lowest in its class

PWM operates at a fixed frequency of 2MHz across the full load range, with ripple <20mVpp (4A full load)

Thermal-optimized packaging: The V-DFN1515-6/SWP (UX-type) packaging employs a 3D thermal design, maintaining 4A continuous output even at 150°C junction temperature

Automotive electronics reliability matrix

Certification Criteria | AP61402Q Parameters | Typical Values of Competitors |

AEC-Q100 Grade 1 | Compliant across the entire temperature range from -40°C to +125°C | Only 85% of devices pass Grade 1 |

HBM ESD | H1C级(±2000V) | ±1000V |

Short-circuit protection recovery time | <2ms (supports 4A instantaneous short-circuit under load) | 5-10ms |

EMI stealth technology

Patented gate drive solution featuring:

Switching node ringing suppression technology (measured reduction of 15 dBμV at 30 MHz)

Programmable minimum shutdown time (110 ns) to prevent inductor current runaway

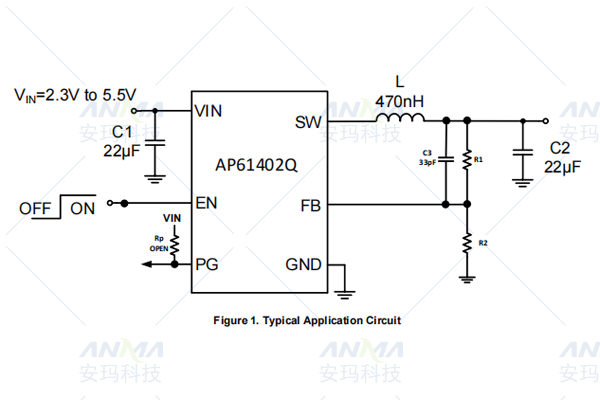

Typical application circuit analysis

In the reference design shown in Figure 1, a complete power supply solution can be constructed using only a 470nH inductor and 22μF input/output capacitors. Compared to traditional asynchronous architectures:

PCB area reduced by 40% (only 15×15mm)

Load transient response improved by 3 times (deviation <200mV during 50mA ↔ 4A transition)

Main applications in the automotive sector:

Instrument panel MCU power supply (supporting ISO 26262 functional safety documentation)

In-vehicle camera modules (compatible with LVDS interface and 1.2V low-noise requirements)

Currently, the AP61402Q has passed pulse immunity testing for 48V mild hybrid systems from German automakers. A smart BMS version with an integrated LIN interface will be launched in Q3.