+86 18038161406

+86 18038161406

SSOP Package Characteristics_Specification Dimensions_Process Flow

SSOP package is a type of integrated circuit (IC) package. It is a small package that is commonly used in high-density and miniaturized electronic devices, such as cell phones, digital cameras, portable audio players, and so on.

SSOP package is a surface mount package, also known as SMT package. It is characterized by smaller size and thinness, which can effectively save space on the circuit board.SSOP packages usually take the form of leads arranged on both sides, which are connected to the circuit board by soldering.

The SSOP package usually has a higher pin density, so it can accommodate more pins and functions. It provides a compact and high-performance packaging solution for applications requiring high-density integrated circuits.

SSOP Package Features

The SSOP package has the following features:

Small size: It is a compact package with a relatively small size that effectively saves space on the board. This makes it ideal for high-density and miniaturized electronic devices.

Thin design: It has a relatively thin design, enabling it to accommodate thin devices. This is useful for applications that require complex functionality to be integrated within a limited thickness.

Surface Mount Technology: Utilizes Surface Mount Technology (SMT), which means its pins are attached directly to the surface of the board through soldering without the need for insertion holes. This provides greater manufacturing efficiency and reliability and simplifies the assembly process.

High Pin Density: Typically has a high pin density and can accommodate more pins and functions. This makes it ideal for ICs that require a large number of signal connections or complex functionality.

Reliability: Soldered connections provide good electrical and mechanical connections with high reliability. It is able to withstand certain mechanical stresses and temperature variations and is suitable for applications in a variety of environmental conditions.

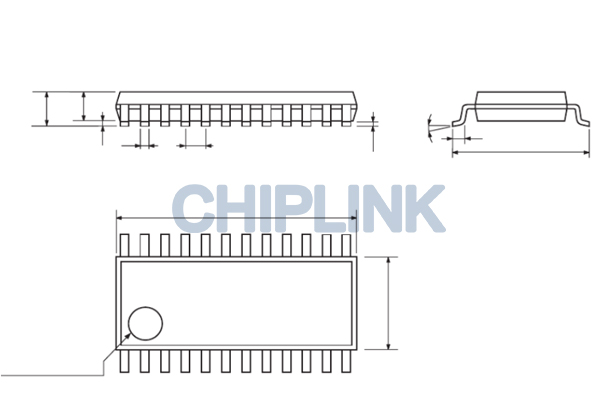

SSOP Package Dimensions

SSOP package dimensions can vary depending on the specific manufacturer and specifications. The following are some examples of common SSOP package sizes (operating temperatures typically: -40°C to +85°C) for reference only:

SSOP-8: With 8 pins, the package size is usually around 2.6 mm x 3.9 mm and the height is around 1.25 mm to 1.45 mm or so.

SSOP-16: With 16 pins, the package size is usually around 4.4 mm x 5.8 mm and the height is around 1.45 mm to 1.65 mm.

SSOP-20: With 20 pins, the package size is usually around 6.0 mm x 6.2 mm and the height is around 1.45 mm to 1.65 mm.

SSOP-24: 24-pin SSOP package, package size is usually around 6.4 mm x 7.8 mm. The height is around 1.45 mm to 1.65 mm.

It should be noted that SSOP packages may have some variations in terms of number of pins, size and spacing from one manufacturer and specification to another. Therefore, when using SSOP packages, the design and layout needs to be based on the specific device specifications and technical documentation provided by the manufacturer.

SSOP Package Process

The process flow for SSOP packages usually includes the following steps:

Substrate Preparation: Prepare the board for packaging. This includes cleaning and coating the surface to enhance soldering and adhesion.

Placement: An automated placement machine is used to accurately place the SSOP package components in their designated locations on the board. The placement machine takes the SSOP package device from the component library and affixes it to the board.

Soldering: The pins of the SSOP package components are connected to the pads on the board through techniques such as reflow soldering or wave soldering. During the soldering process, the solder melts and forms a reliable electrical and mechanical connection.

Cleaning: If required, the board may need to be cleaned to remove residues and contaminants from the soldering process. The cleaning process can be performed using specific cleaning agents and equipment.

Inspection and Testing: The packaged SSOP device is inspected and tested to ensure that its quality and performance meets specifications. This includes cosmetic inspections, reliability testing of solder connections, and functionality testing.

Package Completion: After inspection and testing, the SSOP packaged device is considered part of the completed packaging process and is ready for subsequent assembly and use.

In addition, the specific SSOP packaging process flow may vary depending on the manufacturer and production environment. Therefore, during the actual packaging process, the appropriate steps and controls should be performed according to the process specifications and requirements provided by the manufacturer.

SSOP Package Advantages and Disadvantages

SSOP packages have the following advantages and disadvantages content.

Main Advantages:

Small size: relatively small, allowing for high density pin layout, suitable for electronic devices requiring miniaturization and high integration.

High pin density: higher number of pins can accommodate more functions and signal connections.

Good reliability: Reliable solder connections on the board for applications in industrial environments and high vibration stress.

Good thermal performance: Due to the small package size, SSOP packages have a low thermal resistance, which helps heat dissipation and management.

Wide range of applications: commonly used for medium complexity integrated circuits in consumer electronics, communication equipment, industrial control, etc.

Main Disadvantages:

Higher soldering difficulty: Due to the higher pin density and small package size, the soldering operation of SSOP packages is relatively complex and requires higher soldering techniques and technology.

Repair difficulties: due to the small size of the package and the small pin spacing, if you need to replace or repair the SSOP package device, you need to have fine tools and techniques.

Limited device heat dissipation: Although SSOP packages have some thermal performance, due to the small size of the package, the heat dissipation ability is relatively limited, for high power and high temperature applications, additional heat dissipation measures may be required.

Not suitable for high voltage applications: SSOP packages are usually not suitable for high voltage applications, due to the small spacing between the pins, it is difficult to meet the electrical isolation requirements at high voltages.

Difference between SSOP and SOP packages

SSOP and SOP packages are two common integrated circuit (IC) package types. They have some similarities and also some differences.

Similarities:

Size: Both SSOP packages and SOP packages are small packages with small dimensions. They are both suitable for electronic devices that require high density and miniaturization.

Surface Mount Technology: Both SSOP packages and SOP packages utilize Surface Mount Technology (SMT), where they are attached to the surface of a circuit board by soldering without the need for insertion holes.

Pin Arrangement: SSOP packages and SOP packages have a similar pin arrangement, usually on both sides of the package, with a relatively high pin density.

Points of difference:

Package Size: SSOP packages are smaller and more compact than SOP packages, SSOP packages usually have a higher pin density and can accommodate more pins and functions.

Pin Spacing: SSOP packages typically have smaller pin spacing to accommodate higher density integration. SOP packages have a relatively large pin pitch.

Application Areas: Due to the miniaturization and high density characteristics of the SSOP package, it is usually more suitable for applications that require more functionality and higher pin density. The SOP package is suitable for relatively simple integrated circuits with a small number of pins.

Difference between CSOP and SSOP packages

CSOP packages and SSOP packages are two common types of integrated circuit chip packages, and there are some differences in their package sizes and features.

CSOP package:

Package size: a very small package with dimensions close to those of a chip, hence the name chip-scale size. It has a very compact package size and is suitable for highly integrated electronic devices and miniature products.

Pin Layout: A ball grid array (BGA) or no-lead package (no-lead package) structure is usually used. The pins are located at the bottom of the package and are connected to the board by tiny solder balls.

Thermal Performance: Because CSOP packages utilize a BGA or no-lead structure, the bottom of the package conducts and disperses heat better, providing better thermal performance and heat dissipation.

SSOP Package:

Package Size : SSOP package is smaller as compared to CSOP package but is relatively larger in size. It is a shrink package with smaller dimensions for electronic devices that require high density and miniaturization.

Pin Layout: The pins are located on both sides of the package and are usually thin external pins. The pin spacing is small and adapts to high-density pinouts.

Application areas: Since the SSOP package is relatively small, but still has a certain number of pins and functions, it is suitable for medium complexity integrated circuits, which are widely used in consumer electronics, communication equipment, industrial control and other fields.

Of course, it is necessary to select the appropriate package type according to the specific application requirements and device specifications. In the design, reference should be made to the technical specifications and package drawings provided by the manufacturer to ensure proper selection and layout of the package.