+86 18038161406

+86 18038161406

Six reasons for MOS tube failure

Power devices in recent years the development of the market is very hot, especially MOS tube, he is mainly used in power adapters, battery management systems, as well as inverters and motor control systems.

With the outbreak of calculator motherboards, AI graphics cards, servers and other industries, low-voltage power MOS tubes will once again usher in an explosive market demand.

In the field of switching power supply applications, due to the power supply Controller has been done very well, and most of the Controller for the pure hardware control, manufacturers will generally be on the layout of the wiring and MOS drive to do special optimization, so in the switching power supply applications in the MOS burned out the situation is relatively small, most of the performance for overheating.

But in the battery management system, and motor control system and inverter system, the probability of MOS burnout becomes very large, the reason is that the battery management system to protect the instantaneous current mutation, motor and inverter system in the MOS with the load are very large inductive loads, especially motor control is also faced with the reverse electromotive force brought about by the braking, have put forward a greater MOS tube operating voltage and current. The challenge of the MOS tube operating voltage and current is even greater.

Today we strike while the iron is hot, analyze the six most common failure modes of MOS tubes.

Failure mode avalanche failure avalanche failure refers to overvoltage breakdown, that is, we often say that the voltage between the drain and source exceeds the rated voltage of the MOSFET, and reaches the limit of the MOSFET tolerance, which leads to the failure of the MOSFET.

SOA failure SOA failure refers to overcurrent damage, that is, the current exceeds the MOSFET's safe operating area caused by the failure, generally due to the Id exceeds the maximum value determined by the device specifications, so that the MOSFET's heat loss is too large, the long-term accumulation of heat and the resulting failure.

Electrostatic failure electrostatic failure is better understood, almost any electronic components are facing electrostatic problems, especially in the northern dry winter. It is important to know that the general electrostatic resistance of the MOS tube is 500V, very fragile, so we try to use anti-static bracelets and tweezers when operating the MOS tube in winter.

Gate breakdown gate breakdown refers to the gate suffered abnormal voltage caused by the gate gate oxide layer failure, generally we drive the MOS tube Vgs set at 12V, device manual, although labeled Vth is generally in the 2-5V, but for different Vgs will correspond to different Rdson, so we usually choose 12V or 15V to ensure that the MOSFET is fully open. And this voltage does not have a high voltage resistance like MOS Vds, Vgs is generally limited to 20V, more than 20V will likely to breakdown gate.

After the gate breakdown, the general use of multimeter can be measured, GS between the short circuit, and DS between the normal into a high resistance state.

Resonance failure whether it is a battery management system, or inverter and motor control field, we usually use the MOS multi-parallel design, due to the inconsistency of the parameters of the MOSFET itself will lead to the gate of each MOSFET and the circuit parasitic parameters are different, in the same switching, due to the opening of the order of the problem caused by switching oscillations, and further damage to the MOSFETs, therefore, when used in parallel, must pay attention to the layout and layout of the MOSFET. Therefore, in parallel must pay attention to the layout and wiring, as well as MOS Vth selection and supply chain management, which I will specialize in another article to discuss.

Body diode failure in motor control, bridge rectifier and LLC control systems, we need to use the body of the MOSFET diode to renew the current, generally the reverse recovery time of the body diode will be slower, so it is easy to overpower and lead to body diode failure. Therefore, the general control frequency is relatively high in the system, we need to MOSFET outside the parallel connection of a fast recovery diode or Schottky. Below, we on the over-voltage breakdown and over-current burned and then analyze in detail its failure process and preventive measures

Avalanche failure and its prevention

Simply put, the MOSFET will be superimposed between the drain and source poles of the MOSFET after the high voltage in the system is superimposed on the power supply board due to the bus voltage, the transformer reflection voltage, the motor's reverse electromotive force, the leakage inductance spike voltage, etc. The manual of the MOSFET will generally contain parameters such as single-sided impulse avalanche energy Eas, repetitive impulse avalanche energy Ear, and the single impulse avalanche current Ias, etc. These parameters reflect the power MOSFET's avalanche energy, and they will reflect the power MOSFET's performance. These parameters reflect the avalanche capability of that power MOSFET.

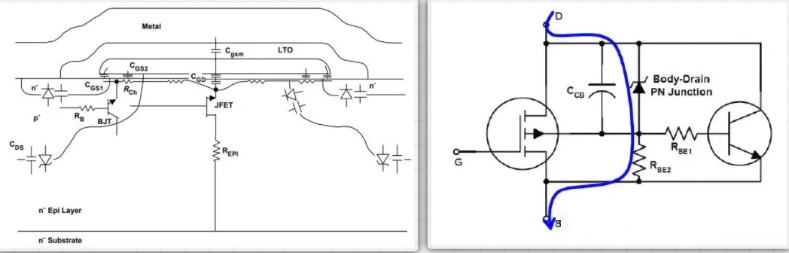

In fact, there is also a parasitic triode in the actual MOSFET, just like the continuity diode between the drain and source, which can be seen in the internal schematic and the corresponding equivalent circuit diagram below:

We can see that this parasitic BJT is directly in parallel on top of the MOSFET, therefore, when the MOSFET drain exists a large current Id and high voltage Vd, the ionization inside the device is intensified, and a large number of hole currents appear, and these currents flow through the Rb resistor to enter the source leads to the base potential of the parasitic transistor rises, that is, Vb will rise, then the parasitic transistor will Conductivity, thus avalanche breakdown, so its internal is due to overvoltage generated by the current flows into the parasitic transistor, transistor conduction, is the same as the MOSFET also conducts.

Preventive measures: avalanche failure is ultimately a voltage failure, so prevention we focus on the voltage to consider. Specifically, you can refer to the following ways to deal with. 1: the use of reasonable derating, the current industry derating is generally selected 80% -95% of the derating, depending on the specific circumstances of the enterprise warranty terms and circuit concerns to be selected. 2: reasonable transformer reflection voltage. 3: reasonable RCD and TVS absorption circuit design. 4: high-current wiring as much as possible to use a thick, short layout structure to minimize the wiring Parasitic inductance. 5: Select a reasonable gate resistor Rg. 6: In the high-power power supply, you can add RC damping or Zener diodes for absorption as needed and appropriate.

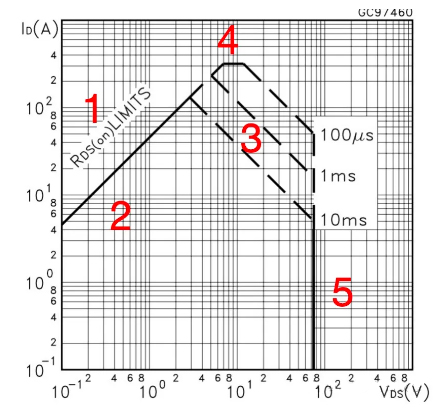

SOA Failure Machine Prevention SOA failure refers to the damage mode caused by abnormal high current and voltage simultaneously superimposed on top of the MOSFET during operation of the power supply, resulting in transient localized heating. Or the chip and heat sink and package can not reach thermal balance in time leading to heat accumulation, continuous heat generation makes the temperature exceed the limit of the oxide layer and lead to thermal breakdown mode. For the parameter limit values of each SOA line, you can refer to the following picture, which is available in the datasheet of each MOSFET.

Below we analyze the meaning of the 5 areas marked in the picture below

This area mainly limits the maximum rated current and pulse current, because the horizontal axis at the moment shows a very low voltage, then more of a high current caused by the failure of the SOA.

In the area of 2 belongs to the area where both current and voltage are safe, but it also depends on the junction temperature of the device (depending on the Rdson size), if the junction temperature exceeds 150 degrees, it can also lead to SOA failure.

In region #3, we can see that it is extended three times depending on the time, corresponding to 10ms, 1ms and 100us, where the main focus is on the power dissipation of the device, which is essentially the value of the maximum current that can withstand 10ms.

In region #4, this is the region where the current value is capped, which refers to the limit of the maximum value of the pulse current, exceeding which will lead to the failure of the SOA.

In area #5, this is a voltage capping area, where the voltage on Vds is mainly limited.

MOSFETs in our circuits, as long as we ensure that the energy device is in the range of the above limitation area (2 and 3), we can effectively circumvent the generation of power supply failure problems due to MOSFETs. Preventive Measures:

Ensure that all power limitations of the MOSFET are within the SOA limit line under the worst conditions.

Make sure to make the OCP function precise and detailed. When doing the OCP point design, you may generally take 1.1-1.5 times the current margin, and then just start debugging the RSENSE resistor according to the protection voltage of the IC such as 0.7V. Also some MOSDrivers have integrated overcurrent protection, you can try that too, it's just expensive.

Reasonable thermal design redundancy is also very necessary, for the rated current and maximum current operating time reliability test is essential, remember to superimpose the operating ambient temperature.